Blog Ecobraz Eigre

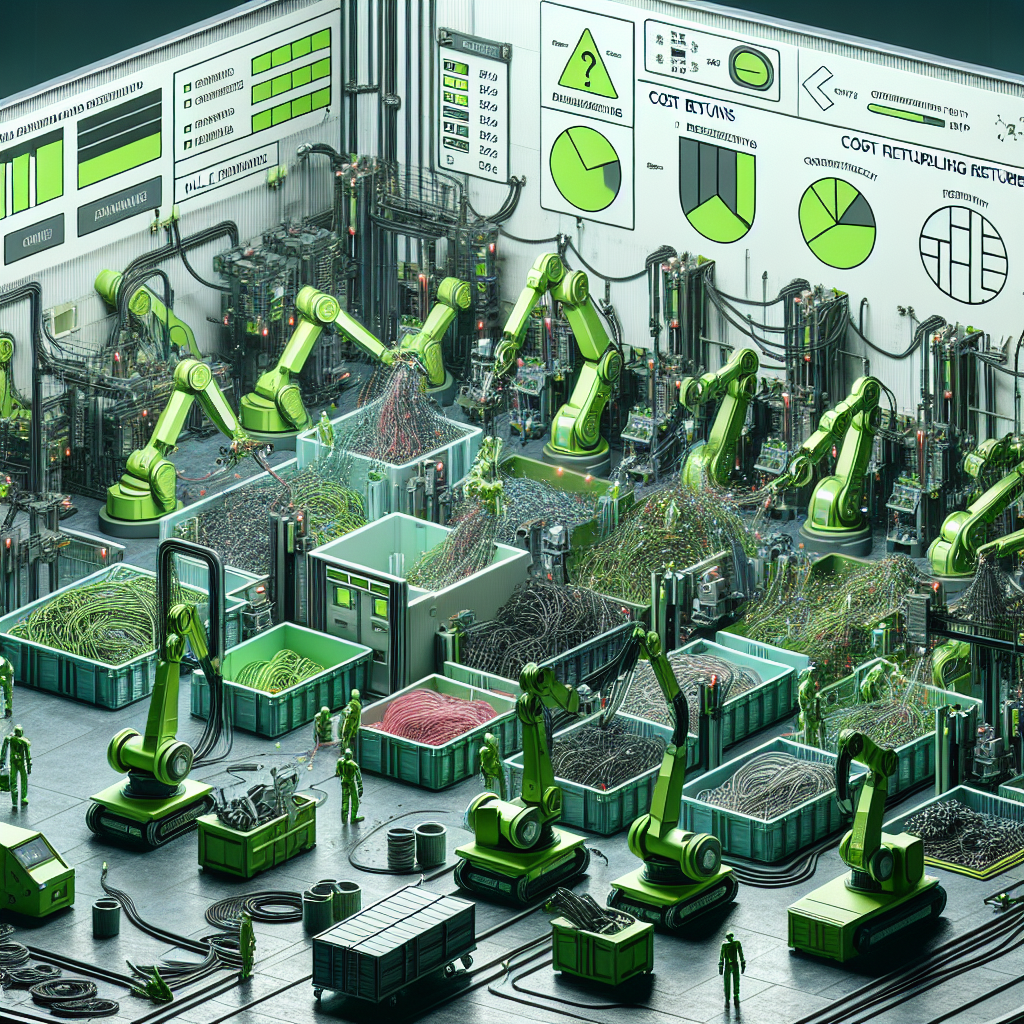

Robotic automation in the disassembly of electrical wires and cables for recycling: costs, returns and feasibility

Introduction to robotic automation in the dismantling of electrical wires and cables

The dismantling of electrical wires and cables for recycling is a crucial stage in the process of reusing materials such as copper, aluminum and plastics. Robotic automation has emerged as an innovative solution that can optimize this stage, reduce costs and increase efficiency.

Benefits of robotic automation in cable recycling

The application of robotics in disassembly provides greater precision, speed and safety in cable handling. Robots are able to carry out repetitive operations with consistency, minimizing human error and reducing the risks associated with exposure to potentially hazardous materials.

Analysis of the costs involved in automation

Initial investments include the purchase of robotic equipment, installation and integration of the systems, as well as the costs of training technical personnel. Periodic maintenance must also be considered to ensure that the robots function properly.

Economic and environmental returns from automation

In the long term, automation can generate significant savings through reduced labor, increased productivity and less waste of materials. Environmentally, the precision of robots contributes to greater metal recovery and a reduction in the impact of improper disposal.

Feasibility and implementation challenges

Feasibility depends on the scale of the operation, the type of cables processed and the financial capacity for investment. Technical challenges, such as the diversity of cable materials and formats, require systems with high adaptability and artificial intelligence for automation to be truly efficient.

Future prospects

With advances in technology, robotic systems are expected to become more accessible and capable of handling an even greater variety of cables. Integration with other technologies, such as computer vision and machine learning, promises to revolutionize the recycling process in a sustainable way.

Deixe um comentário

O seu endereço de e-mail não será publicado. Campos obrigatórios são marcados com *