Blog Ecobraz Eigre

Robotic automation in the disassembly of electrical wires and cables for recycling: costs, returns and feasibility

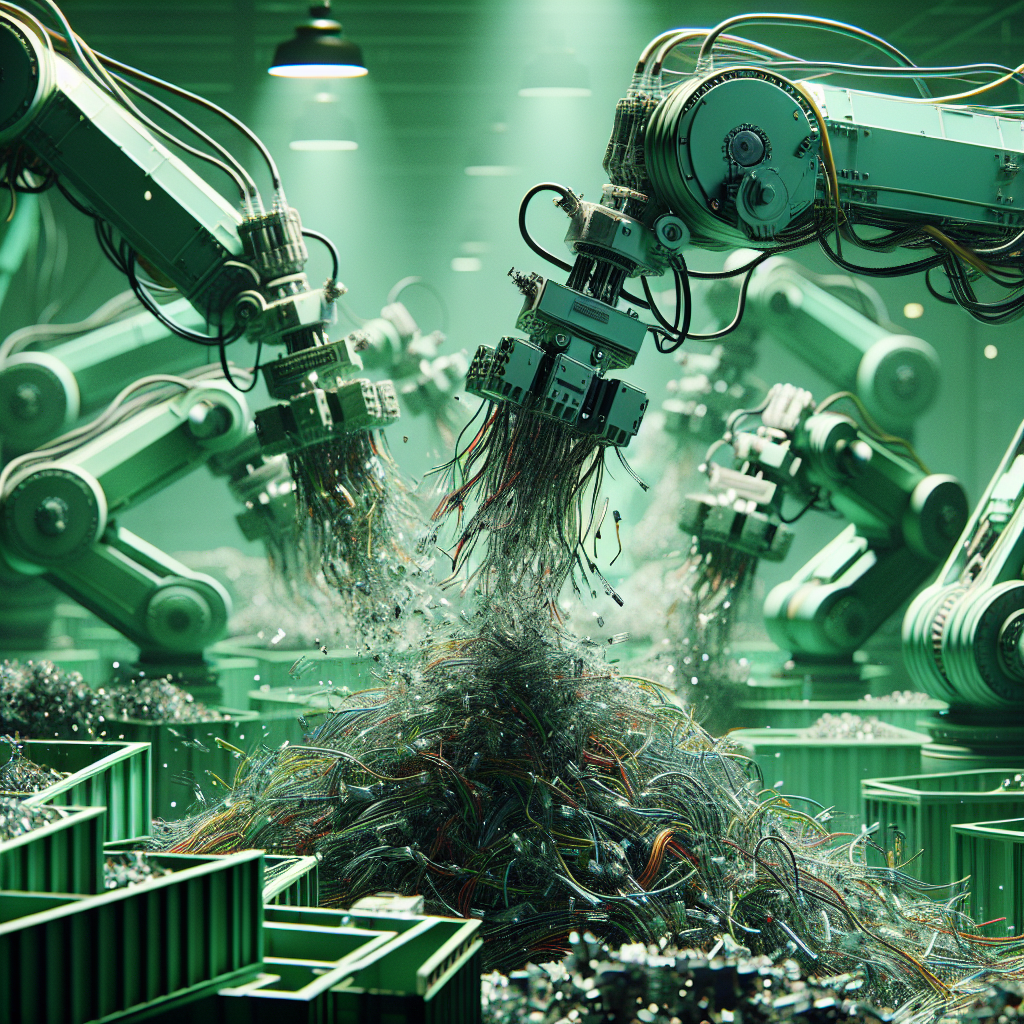

Introduction to robotic automation in the dismantling of electrical wires and cables

The growing demand for efficient recycling of electrical wires and cables has driven the adoption of robotic automation in this segment. Manual dismantling has limitations such as low productivity and high operating costs, while automation can optimize processes, reduce risks and increase the recovery of valuable materials.

Costs involved in implementing robotic automation

Investing in robotic systems for dismantling requires analysis of initial costs, which include equipment acquisition, installation, system integration and personnel training. In addition to these, there are periodic maintenance costs and technological upgrades. Despite the high initial cost, automation tends to reduce labor costs and increase efficiency, positively impacting the cost-benefit ratio in the medium and long term.

Financial and environmental returns

The financial returns come from the greater recovery of copper and other metals present in wires and cables, which have a high value on the secondary market. Automation also reduces losses during the process and cuts dismantling time, increasing operational capacity. Environmentally, this technology contributes to reducing inappropriate disposal, minimizes environmental impact and supports the circular economy by ensuring the reuse of materials.

Technical and operational feasibility of automation

Technical feasibility depends on the complexity of the cables to be recycled and the flexibility of the robots to adapt to different types and sizes. Computer vision and artificial intelligence technologies are essential for the robots to correctly identify and dismantle components. From an operational point of view, it is necessary to assess the incoming flow of waste and integrate the automated system without compromising existing logistics.

Challenges and future prospects

Among the challenges are the high initial investment, the need to constantly update the equipment and integration with established processes. However, advances in sensors, artificial intelligence and collaborative robotics indicate a promising future for automation in this area. The trend is for more affordable and efficient solutions to become popular, expanding adoption and facilitating sustainable recycling.

Conclusion

Robotic automation in the dismantling of electrical wires and cables represents a significant opportunity to optimize recycling, combining operational efficiency and environmental sustainability. Although it involves considerable initial costs, the financial and ecological benefits demonstrate good viability, especially with technological evolution and the growing demand for more efficient recycling processes.

Deixe um comentário

O seu endereço de e-mail não será publicado. Campos obrigatórios são marcados com *