Blog Ecobraz Eigre

Robotic automation in the disassembly of electrical wires and cables for recycling: costs, returns and feasibility

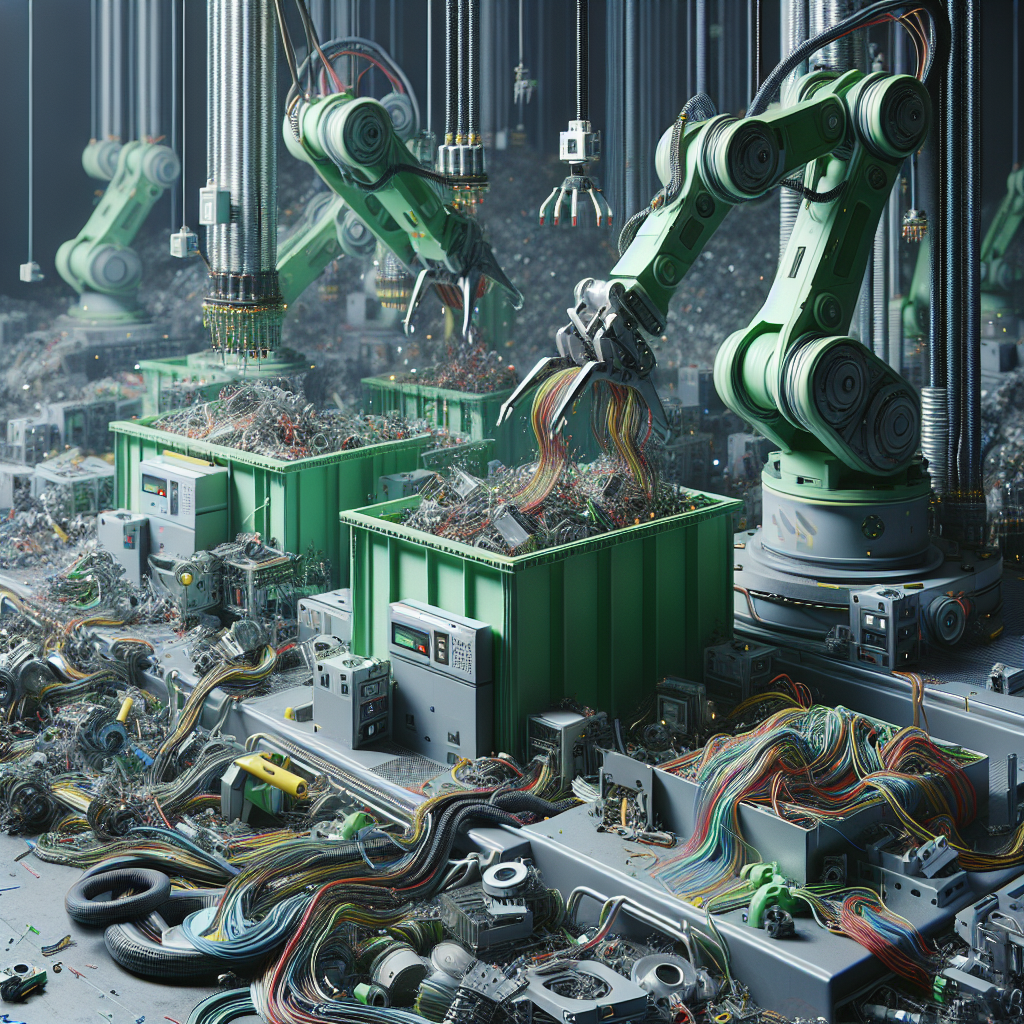

Introduction to robotic automation in the dismantling of electrical wires and cables

The growing demand for sustainable processes has driven the adoption of robotic automation in the recycling of electrical wires and cables. This technology promotes greater efficiency, safety and reduced operating costs, making dismantling more viable and profitable.

Costs involved in implementing automation

The main costs related to robotic automation include acquiring the robots, integrating the systems, maintenance and operational training. Although the initial investment is high, the cost tends to be diluted over time due to the reduction in failures and increased productivity.

Financial returns and economic benefits

Automating dismantling makes it possible to speed up the process, reduce human error and maximize the recovery of copper and other valuable metals. This translates into increased recycled volume and better material quality, reflecting in higher financial returns.

Technical and operational feasibility of automation in dismantling

The feasibility of automation depends on the complexity of the wires and cables, the volume processed and the adaptation of existing production lines. Advanced robotic equipment is being designed to handle different diameters and insulators, ensuring operational flexibility.

Environmental impacts and sustainability

In addition to the economic benefits, automation in recycling contributes to reducing the environmental impact, avoiding improper disposal and promoting the efficient reuse of the natural resources present in electrical cables.

Final considerations

Robotic automation in the dismantling of electrical wires and cables represents an essential strategy for increasing recycling efficiency, balancing costs and returns in a sustainable way. Investments should be analyzed with a focus on the long term and environmental advantages.

Deixe um comentário

O seu endereço de e-mail não será publicado. Campos obrigatórios são marcados com *