Blog Ecobraz Eigre

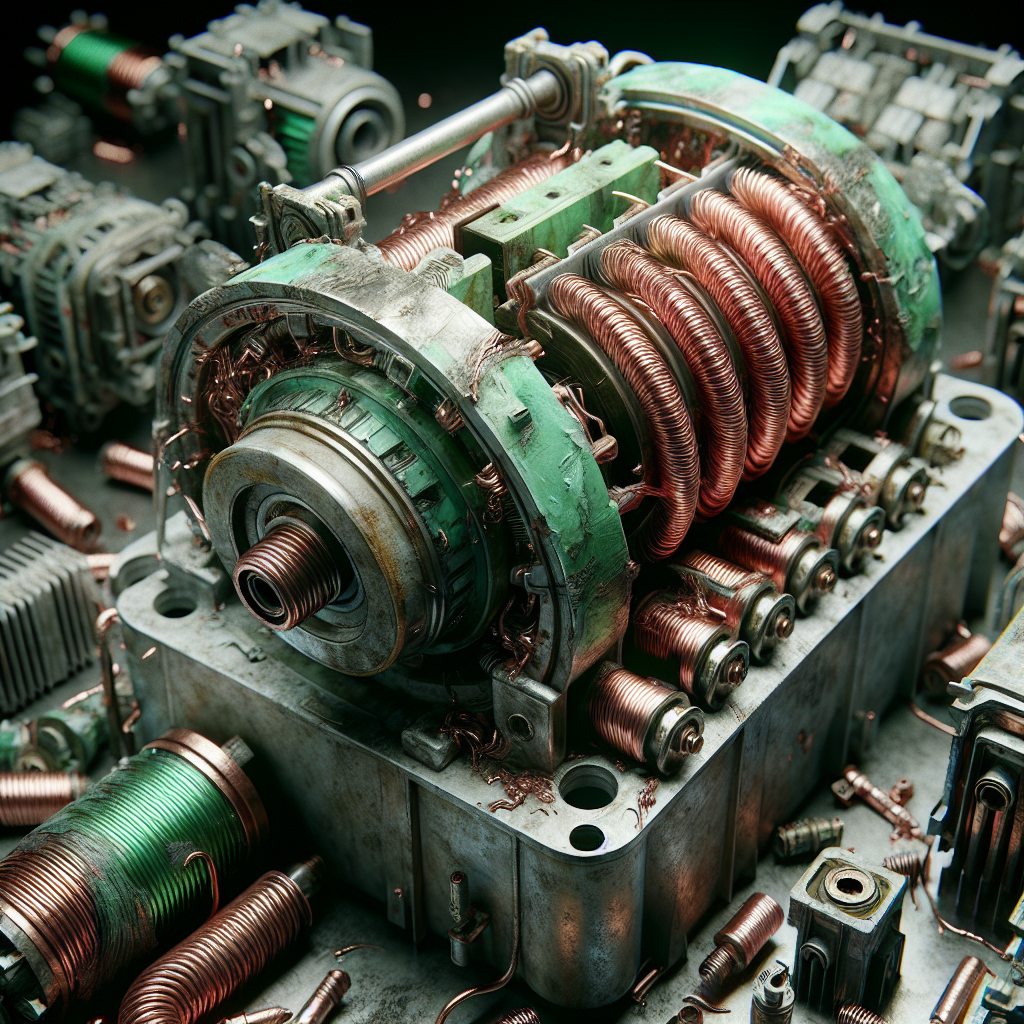

Electric coils and motors: reusing copper and iron

The reuse of copper and iron in electric coils and motors is fundamental to sustainability and the circular economy in the industrial sector. Recovering these metals reduces environmental impacts, complies with current legislation and increases operational efficiency.

Importance of reusing copper and iron

Copper and iron are essential materials in the manufacture of electrical components, such as coils and motors, due to their conductive and magnetic properties. Reusing these metals contributes to conserving natural resources and reducing the volume of solid waste, as provided for in the National Solid Waste Policy (Law No. 12.305/2010, planalto.gov.br).

Recovery and reuse processes

Reuse begins with the proper collection of deactivated electromechanical components, followed by careful disassembly to separate the metal parts, especially copper and iron. Proper separation ensures the purity of the materials for subsequent smelting and reinsertion into the industrial production chain.

In addition, it is essential that the process follows technical standards that guarantee safety and efficiency, reducing losses and environmental impacts. The Brazilian Association of Technical Standards (ABNT) provides specific guidelines for handling and processing these materials.

Legal and environmental aspects

In accordance with the parameters established by the National Solid Waste Policy (Law No. 12.305/2010), the management of metal waste from electrical coils and motors must prioritize reuse and recycling, minimizing disposal in landfills and avoiding soil and water contamination.

The National Solid Waste Management Information System (sinir.gov.br) monitors and guides the correct disposal of this waste, promoting sustainable practices in the public and private spheres.

Technical and operational challenges

The dismantling and processing of materials requires specialized equipment to ensure the efficient separation of metals and the safety of the professionals involved. Investments in technology allow for greater recovery of copper, as well as a reduction in iron losses, increasing the technical and economic viability of reuse.

In cases involving the disposal of electronic media such as hard disks, the correct procedure for the safe destruction of these devices is essential, ensuring the elimination of sensitive data. To schedule specialized services, we recommend accessing: sanitization of electronic hard drives.

Benefits for ESG, EHS, purchasing, IT and legal areas

Decision-makers in these areas should consider that the proper reuse of materials reduces raw material costs, meets regulatory requirements and reinforces the organization's commitment to sustainability and legal compliance. In addition, responsible practices mitigate environmental and legal risks, promoting efficient governance and transparency.

Adopting processes that include the correct collection of electronic waste is essential to ensure a sustainable production cycle. To optimize this stage, it is possible to schedule specialized collection via: electronics collection scheduling.

Final considerations

The reuse of copper and iron derived from electrical coils and motors is a technical practice that contributes significantly to the circular economy, with positive environmental and economic impacts. Compliance with current standards and the adoption of safe procedures guarantee the efficiency and sustainability of the electromechanical production chain.

The continuous development of technologies and the engagement of decision-making sectors are essential to consolidate this practice as a standard in the sector, driving innovation and social and environmental responsibility.

Deixe um comentário

O seu endereço de e-mail não será publicado. Campos obrigatórios são marcados com *