Blog Ecobraz Eigre

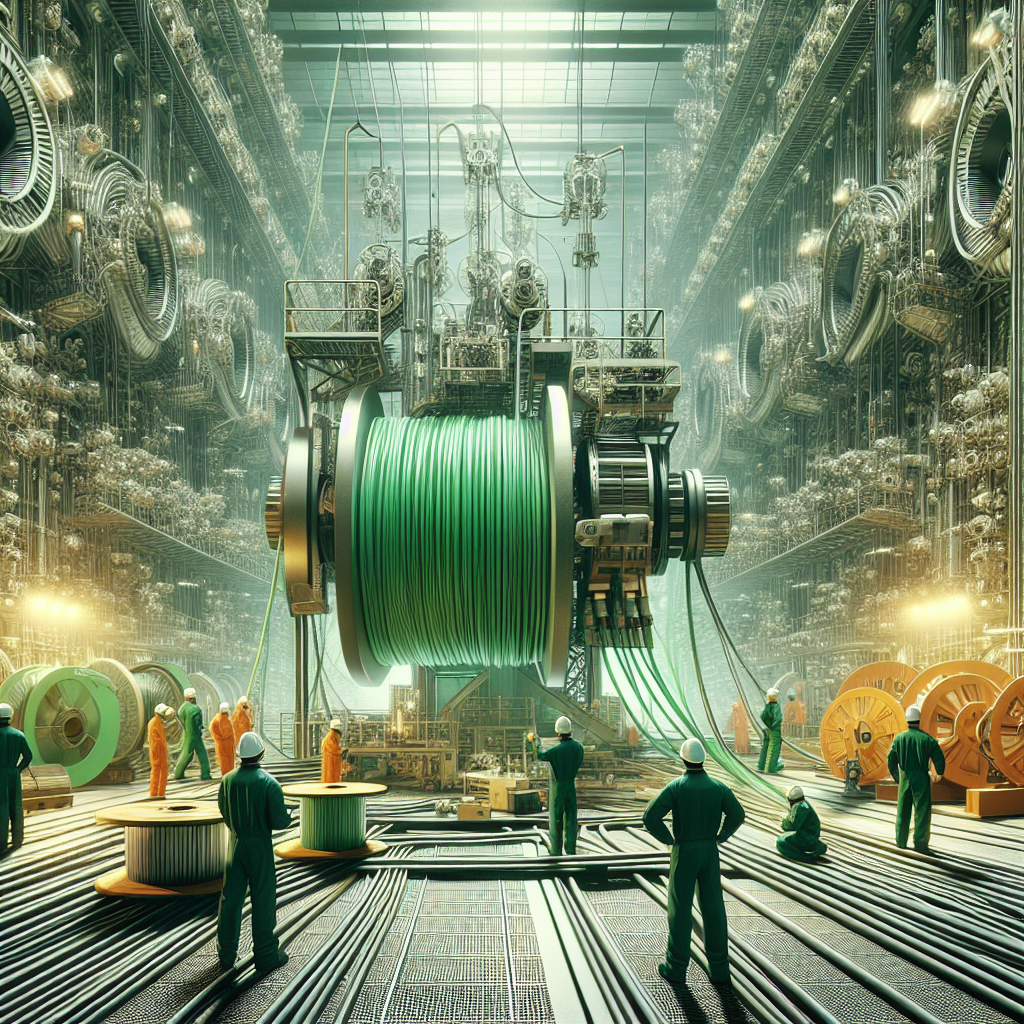

How does the processing of electrical cables and wires work?

Introduction to the processing of electrical cables and wires

The processing of electrical cables and wires is a fundamental stage in guaranteeing quality, safety and efficiency in the use of these essential components in electrical installations. This process involves a number of stages aimed at preparing cables for integration into electrical systems, from manufacturing to final installation, including removing insulation, cutting, crimping and other technical procedures.

Main stages in the processing of electrical cables and wires

The processing of electrical cables and wires comprises a number of important stages that require specific equipment and qualified personnel. The following are the most common stages:

1. Stripping

Stripping consists of removing the insulation from cables and wires, exposing the internal metal conductor for electrical connections. This stage is carried out with specific tools, which cut through the insulating layer without damaging the conductive core, guaranteeing a safe and efficient connection.

2. Cutting and sizing

The cutting of cables and wires must respect standard or project-specific measurements. Automatic or manual equipment is used to cut the wires to the correct size, ensuring uniformity and facilitating installation.

3. Crimping

When crimping, metal terminals are attached to the ends of the wires to make it easier to connect them to other electrical components. This procedure ensures reliable electrical contact, reduces resistance and prevents mechanical wear at the connection points.

4. Twisting the conductors

When working with multiple wires or cables, twisting the conductors may be necessary to improve the mechanical strength and organization of the cabling, as well as reducing electromagnetic interference in some applications.

5. Quality and safety tests

After processing, the electrical cables and wires undergo tests that check for continuity, resistance, insulating capacity and the absence of mechanical flaws. These tests ensure that the products comply with current technical standards.

Equipment used in processing

To carry out all these stages with efficiency and quality, different pieces of equipment are used:

- Automatic stripping machines remove the insulation quickly and accurately.

- Cutting saw: cuts cables and wires into defined sizes.

- Crimping tools: apply terminals to cables with controlled pressure.

- Wire twisters: intertwine conductors to create multi-strand cables.

- Electrical testers: carry out continuity, resistance and insulation analyses.

Importance of correct processing of electrical cables and wires

Proper processing guarantees the quality of electrical installations, providing safety against short circuits, poor contact and faulty connections. It also contributes to the durability of systems, saves energy and avoids costly rework.

Environmental considerations in processing

The handling and processing of electrical cables must also consider sustainable practices, such as the reuse of metallic materials and the proper disposal of the waste generated. The correct disposal of leftover electrical cables and wires helps to reduce environmental impact and promotes the reuse of raw materials.

Conclusion

The processing of electrical cables and wires involves technical procedures that guarantee the efficiency, safety and quality of electrical systems. From stripping to final testing, each stage is essential for the proper performance of components in a variety of industrial, commercial and residential applications.

Deixe um comentário

O seu endereço de e-mail não será publicado. Campos obrigatórios são marcados com *